Canadian Historic Sites: Occasional Papers in Archaeology and History No. 10

Glassware Excavated at Fort Gaspereau, New Brunswick

by Jane E. Harris

Artifacts from the Post-Occupation Period

Artifacts from this period are varied and include liquor bottles,

beer bottles, beverage bottles, a paneled bottle, food storage

containers and tumublers. There are only a few examples of each type;

nevertheless, a wide number of manufacturing techniques are

represented.

Liquor Bottles

Liquor bottles were found in the north, south and west palisade and

ditch trenches and the proposed British officers' quarters. One bottle

is represented by a base-body fragment that has been made in a turn or

paste mould. The glass, black in reflected light, is olive green (7.5Y)

with a shiny surface. The body is cylindrical, 79 mm. in diameter and

marked by horizontal striations from being turned in the mould. It has

an extant height of 133 mm. The base is 79 mm. in diameter and has a

concave, tiered basal surface. The tiers are formed by smooth, flattened

ridges with diminishing diameters. The central portion of the basal

surface is flat, 29 mm. in diameter and has an orange-peel texture.

There are no signs of wear on the bearing surface. A small, irregular

depression occurs on the interior of the bottle at the base-body

junction. This could possibly be a result of carrying the bottle to the

lehr upon a metal rod inserted through the mouth of the bottle. Such

a method, illustrated by Moser (1969: Taf. 2) and Kendrick (1968: 168)

could easily cause a mark in the area of the base-body junction.

Since there is no pontil mark on this bottle, its earliest possible

date of manufacture is in the 1850s (Scoville 1948: 17). Turn moulds,

however, were popular in the United States in the 1870s (Toulouse 1969b:

532) and were used well into the first quarter of the 20th century

during the gradual change-over to automatic bottle machines (Davis 1949:

213-14).

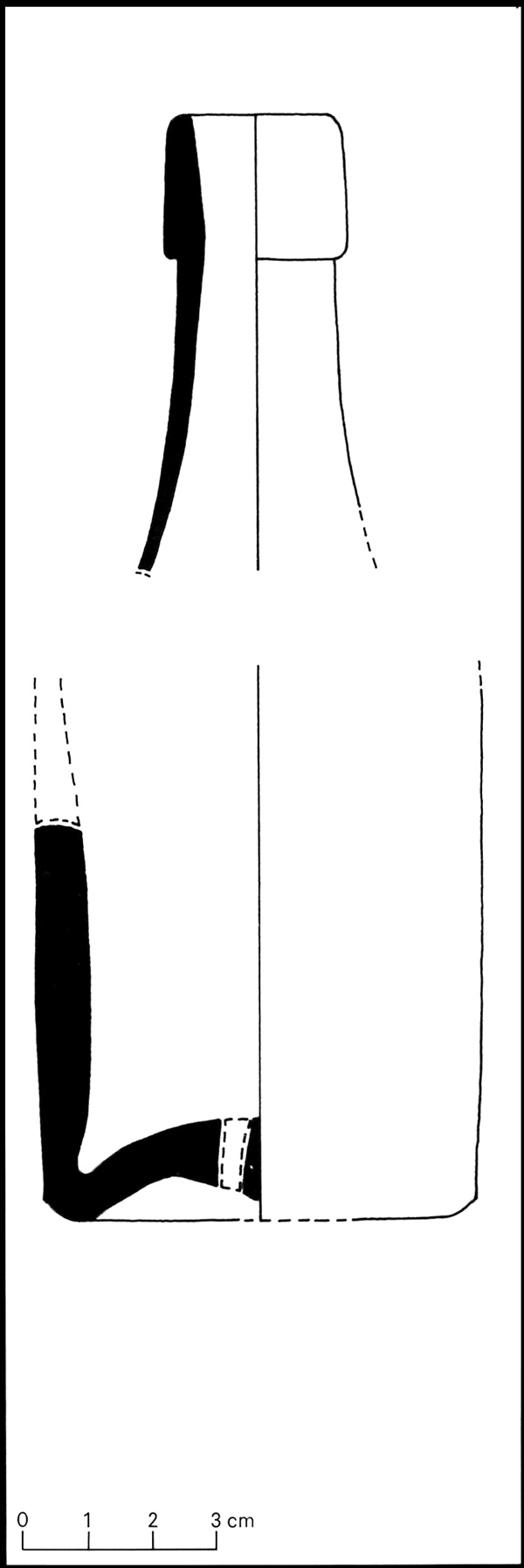

A second bottle is represented by a complete neck of glossy, pale

green (2.5G) glass (Fig. 15). It has been mouthblown in a mould and

after removal from the mould, finished by hand with the aid of a

finishing tool. The neck is bulged, 85 mm. high, 27 mm. in diameter

below the finish, 38 mm. at mid-neck and 36 mm. at its base. A pair of

faint vertical mould lines bisect the neck ending under the finish. The

finish, which is 25 mm. high, consists of a flat tip 14 mm. high and

30mm. in diameter; a down-tooled string rim 6 mm. high and 30 mm. in

diameter, and a stopper-finished bore.

15 Hand-finished liquor bottle neck with stopper-finished bore

(1E3C5-3).

|

Stopper finishes were designed to accommodate stoppers and shell

corks; that is, plain glass stoppers with a tube of cork over their

shank. They were in use at least as early as 1887 as they appear in the

Whitall, Tatum and Company catalogue of that year and were probably used

until the 1920s when the standardization of the continuous thread

closure made many types of closures uneconomical (Lief 1965: 26). A

bottle of this type, called a "sloe gin," appears on page 22 of the

Dominion Glass Company's Bottlers Glassware Catalogue No. 13

published in the 1920s (Rosewarne: pers. comm.).

A third bottle, a shoofly flask, is represented by a neck (Fig. 16)

of glossy pale blue-green (2.5BG) glass. This bottle would have been

manufactured in the same fashion as the previous bottle and is

hand-finished with a flat lip, down-tooled string rim and

stopper-finished bore. The lip is 15 mm, high and 28 mm. in diameter,

and the string rim is 7 mm. high and 24 mm. to 26 mm. in diameter. The

neck is very short, 36 mm. high and bulged, having diameters of 24 mm.,

26 mm., and 26 mm. respectively. Two vertical mould lines bisect the

neck ending a few millimetres below the finish.

16 Hand-finished shoofly flask neck with stopper-finished bore

(1E?N1-5).

|

The finish on this bottle is much neater than the previous bottle, a

feature which suggests that the earliest date of manufacture is 1870,

the date of the invention of the gas-fired glory-hole, by which more

intense heat could be localized on the neck while it was being reheated

to take the excess glass for the finish (Toulouse 1969b: 534). A better

weld was then possible, resulting in a more uniform finish. The bottle

may thus be dated from the years between 1870 and the first quarter of

the 20th century when machine-made bottles made up 90 per cent of the

total bottle output in the United States (Davis 1949: 213-14).

Possibly a fourth and fifth bottle are represented by a finish

fragment and a body fragment both of shiny, pale green glass.

A sixth bottle, machine-made, is represented by three green (7.5GY)

body and neck fragments. The fragments show evidence of having been

burned. The body is cylindrical and bubbled with a vertical mould line.

The neck is bulged and has a vertical mould line and its shadow (the

blank mould line) an indication of machine manufacture. The bottle dates

after 1903 when machines were first used for commercial production of

narrow mouthed ware (Davis 1949: 208).

Two more fragments represent a seventh and possibly an eighth bottle.

They are from the rounded shoulder of a machine-made amber (5YR) flask

dating after 1903.

Another flask is represented by a rounded shoulder fragment. This

flask was machine-made and has a purple tint resulting from the use of

manganese as a decolourizer, consequently placing the manufacture of

the flask between 1903 and World War I, after which manganese was no

longer readily available as its main source had been Germany (Toulouse

1969a: 534).

Beer Bottles

Possibly five beer bottles are represented by fragments found mainly

in the commandant's quarters but also in the north, south and west

palisade and ditch trenches.

One specimen (Fig. 17) is a pint-sized lager-shaped beer bottle of

glossy green (5GY) glass. It has been mouth blown in a mould and

hand-finished. Marks on the base indicate that a base plate may have

been inserted in the mould.

17 Neck and body of a hand-finished lager-shaped beer bottle

(1E3C5-4).

|

The body, extant to a height of 87 mm., and the base are 67 mm. in

diameter. The lower portion of the body is dotted with an orange-peel

texture. No vertical mould lines are present on the body fragments;

however, there are two horizontal ones in the basal area. One encircles

the body-base junction, the other encircles the basal cavity. Embossed

rather crudely within the basal cavity is a number "53..." or "63..."

placed in an arc over an embossed, inverted tear drop. The number may

refer to the mould number while the tear drop could be the symbol of the

company which made or used the bottle. The neck, extant to a height of

72 mm., is tapered with a slightly concave profile. It is vertically

striated and is bisected by two vertical mould lines which end under the

finish. Its diameter at this point is 25 mm. while 35 mm. lower it is

34 mm. The finish consists of only a flat lip 21 mm. high and 28 mm. in

diameter. It has been well formed by a finishing tool. This is the type

of finish commonly associated with swing-type closures, such as the

Lightning stopper, which were being developed in the late 1870s and

early 1880s (Putnam 1965; Lief 1965: 15-16).

The bottling of beer became extremely popular after Louis Pasteur's

invention of pasteurization and study of fermentation in the 1870s (Lief

1965: 15). Since this bottle is hand made it is reasonable to place its

date of manufacture in the period between the 1880s and the first

quarter of the 20th century.

Three other beer bottles may be represented by several turn-moulded

fragments in green glass. All have cylindrical bodies and elongated

shoulders indicative of the lager shape. It is by their shape and green

colour (5GY) that one would suppose them to be beer bottles.

At least one machine-made beer bottle is represented by four amber

(7.5YR) fragments. It is a modern bottle, the type having a rounded

shoulder and cylindrical body with a very short neck.

Soda Bottles

Soda bottles or soft drink bottles number at least four represented

by fragments found in the northeast bastion, the north palisade and

ditch trenches and the proposed barracks.

At least one example of a mineral or soda water bottle is present.

This specimen (Fig. 18) consists of five neck, shoulder and body

fragments in a typical pale aqua (7.5G) glass. The bottle has been blown

in a mould but it is difficult to say whether by mouth or machine. The

neck is striated and flows into an elongated shoulder. The cylindrical

body has been embossed by means of a removable letterplate which fits

into the body of the mould (Fig. 14). The lettering reads: AMHERST

MINERAL WATER COMPANY TAYLOR AND TENNANT, PROP.] (Vienneau 1969:

23).

18 Body fragment from an embossed soda water bottle [1E3P1-9).

|

Taylor and Tennant were soda and mineral water manufacturers in

Amherst, Nova Scotia, who operated from approximately 1902 to 1914

(Vienneau 1969: 36). This bottle was thus manufactured between these dates,

possibly in a Nova Scotian glasshouse such as the Humphreys Glassworks

which was in operation at Trenton, Nova Scotia, at this time (Stevens

1967: 62).

Two more fragments of pale aqua (2.5BG) glass may be from a soda

water bottle. They are from a cylindrical bottle that has been blown in

a mould either by mouth or machine.

A third bottle is machine-made of clear glass with fine, regular

horizontal striations. The body is cylindrical and present to a height

of 105 mm. The shoulder appears to be elongated, while the neck is

cylindrical, flaring towards its base to join the shoulder. It has a

crown finish with a lip 26 mm. in diameter and a string rim 28 mm. in

diameter. Horizontal mould lines encircle the inside edge of the lip

and the neck 2 mm. below the finish. Vertical mould lines bisect the

bottle. Since this bottle has been machine-made, its date of manufacture

falls somewhere after 1903.

Another machine-made bottle is represented by a crown finish. The

glass is clear and has a finely striated texture indicative of its

manufacture on a machine. Horizontal mould lines encircle the inside

edge of the lip and the neck 2 mm. below the finish. Two vertical mould

lines and their shadows bisect the neck. The lip is 26.5 mm. in diameter

while the string rim is 28.5 mm. in diameter. Embossed on the string rim

are the letters "HI" or "TH" if the fragment is inverted. It is not

known what purpose these letters serve. The neck is bulged beginning at

a point approximately 10 mm. below the finish.

Paneled Bottles

The only example of a paneled bottle from the site, a specimen which

appears to be machine-made of pale blue-green (2.5BG) glass, was found

in the large north palisade and ditch trench. The fragment is from a

bottom corner of the body base and bears parts of two recessed panels

separated by a chamfered corner. On one panel, reading down the bottle,

are the neatly embossed letters ". . . TION" in an upper case, sans

serifs face. A horizontal mould line separates the body from the base

just above the resting point. Glass distribution in the base is very

uneven, and no marks are present on the base. Paneled bottles date back

to the 1850s (Rosewarne: pers. comm.); however, as this bottle appears

to have been machine-made it was probably manufactured after 1903. The

bottle was quite probably filled with Dr. Pierce's Favorite

Prescription, a popular American remedy for a variety of "female

complaints" introduced after the 1870s (Wilson & Wilson 1971: 70,

132) and still available in New Brunswick today.

Miscellaneous Bases

There are five bases or base fragments belonging to this period which

cannot be identified as to function.

One fragment is from a pale green (2.5G) oval or possibly

kidney-shaped bottle found in the area of the proposed barracks. It is

difficult to say whether it was mouthblown or machine-made. A very

faint vertical mould line extends down the body ending at the heel. A

flat bearing surface encircles a flat basal depression. All of the edges

on the fragment are rounded, possibly from being burned.

Another fragment from the small north palisade and ditch trench is

from a second base of pale turquoise (5G) lightly bubbled glass. The

base is circular, approximately 75 mm. in diameter. Again, it is

difficult to determine whether it was mouthblown or machine-made. The

texture of the glass would suggest machine manufacture,

thus dating it after 1903. At the centre of the concave basal surface

is a symbol or trademark composed of five embossed dots forming an X. A

horizontal mould line separates the body from the base.

The last three bases are all machine-made and all therefore were

manufactured after 1903. They each have a similar set of mould lines:

vertical down the body, horizontal around the base-body junction and

circular inside the bearing surface.

The first of these is a heavy amber (7.5YR) base, 66 mm. in diameter,

from the northeast bastion. The basal surface is depressed but slightly

convex. At its centre is a very faint series of concentric circles, the

largest of which is 21 mm. in diameter. Encircling this is an

additional mould line 38 mm. in diameter, formed most likely by a base

plate.

The second base, from the southwest bastion, is green (7.5GY) and 81

mm. in diameter. The basal surface is depressed, becoming slightly

convex at its centre. This base is plain and exhibits no embossed

trademark.

The last base, also from the southwest bastion, is represented by a

body base fragment of clear glass. It is either from a narrow

cylindrical bottle or a flask with rounded ends. Enough of the basal

surface is present to show a flat resting point encircling a concave

depression.

Food Storage Containers

There are at least three and possibly four different types of food

storage containers recovered from the site. They include a Crown fruit

jar and lid, a jelly jar and two modern clear glass jars with continuous

thread finishes.

Crown fruit jars are uniquely Canadian (Toulouse 1969a: 74) and were

manufactured at several glasshouses in Canada. There are over 60

variations of the crown emblem which appears on the body of the jar and

the lid (Bird, Bird and Corke 1971: 24-35).

The Crown fruit jar from Fort Gaspereau was found in the

commandant's quarters (Fig. 19). It consists of a base and 11 body

fragments of shiny pale green (2.5G) glass mouthblown in a mould. Its

body is cylindrical and 101 mm. in diameter with an extant height of 75

mm. Embossed on the body 40 mm. above the base is the word CROWN in

upper case letters with serifs. The crown emblem is represented on only

two small fragments although enough is present to distinguish its

rounded shape. The heel, wide and rounded, joins a footed base which is

79 mm. in diameter. From the outside edge of the bearing surface an

uneven, vertical mould line extends up the body. Within the bearing

surface is a convex depression 1 mm. to 2 mm. in height and 50 mm. in

diameter, bearing a large embossed "B" and its faint second impression

caused when the still malleable glass was centred in the mould (Toulouse

1969a: 537).

19 Base and body fragment of a Crown fruit jar (1E4H1-5).

|

The end manufacturing date of this jar probably lies between the

years 1897 and 1906, the period of transition from mouthblowing to the

full use of automatic machinery for jars (Bird, Bird and Corke 1971: 9).

It could date as early as 1867 when the first Crown jars are believed to

have been made at the Hamilton Glass Works (Bird, Bird and Corke 1971:

24). A possibility exists, however, that the B on the base of the jar

signifies the Burlington Glass Works, a company that made Crown jars and

which was in operation from 1875 to 1909 (Stevens 1967: xiv).

Figure 20 illustrates a pressed glass, outer seal fruit jar lid of

pale turquoise (7.5BG) glass also found in the commandant's quarters. It

may represent a second jar or may have been used on the jar just

described. Lids were easily separated from their original jars and

subsequently were used and possibly discarded, as this one was, with

other jars.

20 Outer seal Crown fruit jar lid, a face view and profile,

b top view looking through glass at embossed emblem (1E3B1-9).

|

The top of the lid, 72 mm. in diameter, is concave to a depth of 5

mm. so that its inner surface extends slightly down inside the mouth of

the jar (Fig. 20,a). The inner surface bears an embossed angular crown

emblem known as a "ring" type (Bird, Bird and Corke 1971: 26). The outer

rim of the lid has a downward projection designed to fit over the lip

and come to rest on a bead or ring on the neck of the jar. Horizontal

mould lines mark the inner edge of the rim and the junction between the

rim and the top of the lid.

This style of crown emblem was manufactured by the North American

Glass Company, the Diamond Glass Company and the Diamond Flint Glass

Company (Bird, Bird and Corke 1971: 27). Their combined operations cover

the years from 1883 to 1913.

The second type of storage container, a jelly jar, is represented by

three fragments from the east palisade trench. The jar is circular in

cross-section with a body tapering toward the base. It has a Phoenix

finish designed to take a metal lid. This finish consists of a plain

lip, in this case 5 mm. high and approximately 65 mm. in diameter, with

a flat projection of glass below it 10 mm. high and approximately 70 mm.

in diameter. "Chill wrinkles," or ripples, appear on the body just above

the base, indicating the jar was pressed (Rose 1964: 11-12). The bearing

surface is flat and shows signs of re-use. It encircles a shallow,

concave basal depression 3 mm. high. Mould lines encircle the inside

edge of the lip, the lower edge of the finish and possibly the outer

edge of the basal depression.

The earliest date of manufacture of this jar is 1892 when the Phoenix

closure was invented (Lief 1965: 20). A similar jar appears in the

Dominion Glass Company's Packers' Glassware Catalogue No. 11a (p.

48) published sometime after 1913 when the Dominion Glass Company was

incorporated. Since the fragments have a purple tint from the use of

manganese as a decolourizer, the jar must have been manufactured before

the end of World War I (Toulouse 1969a: 534).

Two modern, machine-made jars of clear glass are represented by

fragments from the south and west palisade and ditch trenches. The

fragments from the west trench have been badly burned; however, an

embossed triangle enclosing a figure is visible on the fragment. This

may be the Consumers Glass trademark which was not used until 1917

(Stevens 1967: 54). Fragments from the south trench include part of the

jar finish; a lug finish which is a variation of the continuous thread

finish. This jar was probably manufactured after 1924 when finish sizes

were finally standardized (Lief 1965: 27).

Tumblers

One of three non-lead glass tumblers recovered is pressed clear glass

with a yellowish tint. It was found in the area of the commandant's

quarters. The body is circular in cross-section, with a diameter of 78

mm. at the lip, tapering to 60 mm. at the base and an over-all height of

98 mm. The lower part of the body is encircled by a band of 18

rectangular indentations which are 25 mm. high and approximately 10mm.

wide. The basal surface consists of a flat indentation 3 mm. high and 47

mm. in diameter. A circular mould line similar to a blank mould line

appears off-centre on the basal surface.

The yellowish tint in the tumbler could be due to the presence of

selenium in the glass. Selenium was used as a decolourizer in place of

manganese after World War I (Toulouse 1969a: 534). Tumblers similar to

the above appear in the Butler Brothers' Catalog No. 2233 (n.p.)

from the year 1925 and the Dominion Glass Company's Packers'

Glassware Catalogue No. 11b (p. 71)

The second clear glass tumbler is from the southwest bastion. It has

been pressed but has been neatly fire-polished so the exterior surface

is very shiny and smooth. The tumbler is circular in cross-section with

a pattern of alternating concave panels approximately 15 mm. wide and

mitres 6 mm. wide. The design does not continue for the full length of

the tumbler. Attributing a specific date in this case is difficult;

however, the tumbler is most likely of modern manufacture.

The third tumbler, also of clear glass, is represented by a rim

fragment from the proposed barracks. The lip is approximately 65 mm. in

diameter and has been fire-polished. The body appears to have a

cylindrical shape. Once again it is difficult to date such a tumbler but

it is most likely representative of the 20th century.

|