|

|

|

Canadian Historic Sites: Occasional Papers in Archaeology and History No. 6

The Excavation and Historical Identification of Rocky Mountain House

by William C. Noble

Artifact Descriptions (continued)

TOOLS AND HARDWARE

This category of artifacts represents 1.7 per cent of the total

inventory and includes 19 different types of commodities. Noticeably

absent are heavy implements and large iron items of hardware,

suggesting that these items were salvaged at the end of the fort's

occupancy.

Sir George Simpson gives some interesting comments on the nature and

high value of ironware sent to the northwest by the Hudson's Bay Company

in 1820-21. He states (1938: 407-8) that ironmongery in general was vital,

but of poor quality.

Table 10: Tools and Hardware Item |

| Item | Number |

|

| Nails | 100 |

|

| Copper rivet | 1 |

|

| Copper tack | 1 |

|

| Iron hoops and fragments | 37 |

|

| Files | 3 |

|

| Iron punches | 2 |

|

| Offset awls | 2 |

|

| Cold chisel | 1 |

|

| Wedges | 2 |

|

| Knives | 4 |

|

| Whetstones | 2 |

|

| Latch | 1 |

|

| Pintle | 1 |

|

| Window glass | 2 |

|

| Threaded lead tube | 1 |

|

| Silver fragment | 1 |

|

| Copper strap | 1 |

|

| Sheet copper fragments | 14 |

|

| Tin fragments | 23 |

|

| Total | 199 |

|

The supplies of this Department [Athabasca] generally

speaking are of good quality, the Ironmongery excepted. . . . The ice

Chissels are badly tempered. . . . Our Iron Work is the most important

article of Trade in this Country.

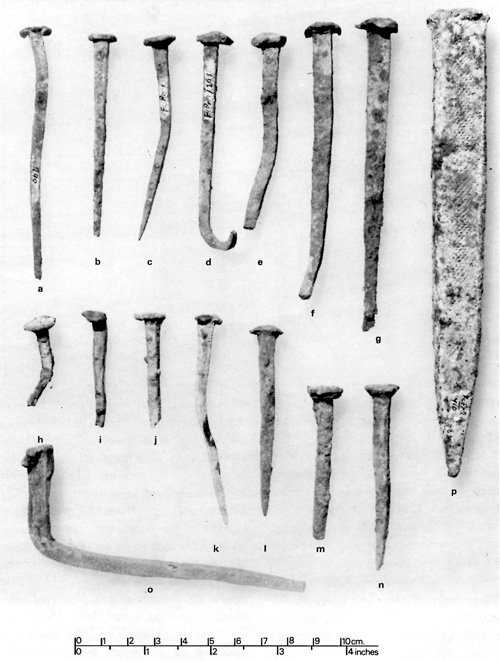

47 Rivets, tacks nails, a, rough machine-made copper rivet

(pre-1820): b, copper upholstery tack from pit 1: c,

upholstery nail (pre-1800); d, part rose, cut nail, 2d

(post-1810): e, flat stamped nail (1825-30); f, small flat

cut nail, 3d (post 1810); g, flat rectangular cut nail, 3d

(post-1810); h, wrought iron rosehead, 6d (pre-1800); i,

flat square-cut nail, 4d (post-1810); j-k, flat cut nails

(post-1810); l, flat machine-cut nail, 7f (ca. 1825); m,

flat machine-made nail, 7d (1800? ); n, part head, wrought with

chisel point, 8d (pre-1800); o-p, hand-wrought rosehead nails

with chisel points, 8d (pre-1800); q, part rose, cut nail, 3d

(post-1810); r, rose rectangular cut nail, 4d (post-1810);

s, rose rectangular wrought nail, 5d (pre-1800): t,

rosehead wrought brad, 6d (pre-1800); u, rosehead, cut common

nail, 7d (post-1810); v, rosehead wrought nail, 5d (pre-1800);

w, broken nail; x, rosehead wrought and cut nail, 7d

(1820); y, large rectangular head early machine nail (post-1810).

|

One of the firms supplying the Hudson's Bay Company with ironware at

this time was that of Messrs. Moreton and Foster (Simpson 1938:

407).

Table 10 enumerates the ironware tools and hardware recovered during

excavation at Rocky Mountain House.

Nails

The nails from Rocky Mountain House are extremely useful for

dating purposes (Figs. 47; 48; 49). Of all the specimens recovered, 100

are analyzable; others are too fragmented or corroded.

The temporal span of Rocky Mountain House encompasses the important

technological transition from wrought to cut and stamped nails during

the 40-year period between 1790 and 1830. In his letter of 27 April 1967

to the author, Dr. Allan B. Dove of the Steel Company of Canada

remarks:

The dating of these nails is indicated by the general form and the

machines in existence at that time. It is pointed out in my report that

there are three general periods represented:

(a) Wrought nails produced prior to 1800.

(b) Cut nails produced between 1810 and 1825.

(c) Early stampings produced between 1820 and 1830.

There is no evidence that any samples in this group were made on

completely automatic machinery or from modern steels.

The following are Dr. Dove's (1967: 2-3) distinctions between

wrought, cut and stamped nails.

Regardless of size, wrought nails can readily be distinguished

from square cut nails on the basis of the following features:

1. Wrought nails taper on all four sides of the shank toward the

point, rather than on two opposite sides as in the case of square cut nails.

2. Wrought nails vary in thickness throughout the length of the

shank because of their having been hand forged. Square cut nails exhibit

uniform thickness because of their having been cut from a plate of

uniform thickness.

Some of the nails in this sample are both cut and wrought. By this I

mean that they have been cut from plate and then finished on the anvil.

Notable examples are Nos. 871, 122, and 645. In these cases, the nails

were first cut from a sheet or strip and then a separate

operation of finishing was carried out.

3. Striations, or parallel shear marks from the cutting blades used

to make square cut nails, would not be found on the shanks of wrought nails.

Practically all the nails of this sample, however, are too rusty and

too deeply pitted to show up this identification criterion.

None of the nails in this sample shows the characteristic shaping of

the shank which is evident on a machine-produced nail, but a few

examples would appear to indicate the use of one of the early machines,

notably Nos. 691, 612, 415, 417, 64, 645 and 100.

It is also notable that until the 1830s, most cut nails can be

distinguished by the fact that the iron fibres run crosswise to

the shank while later cut nails have a fibre structure parallel to

the shank (Nelson 1963: 6).

A stamped nail by contrast is one in which the nail head has been

stamped by machine rather than by hand. Fontana and Greenleaf (1962: 46)

report that:

Between 1825 and 1830 the stamped heads were rather thin and

lop-sided. After 1830 they became less thin, more uniform, and

comparatively square.

Three nails of this type occur in the Rocky Mountain House sample,

notably Nos. 415, 417 and 691. Figure 48 depicts the main nail types

recovered from the fort.

As an introduction to wrought and cut iron nails, Dr. Dove's (1967:

1-2) historical outline is pertinent and helpful.

48 Nail types. a, left, drawn point, right chisel point

roseheads; b, L-head: c, large rectangular head (early machine);

d, csk. wrought; e, flat stamped; f, flat cut.

|

Wrought and Cut Iron Nails.

Background. The first iron factory in Canada was established by

Talon on the site of rich iron deposits in the St. Maurice Valley

between Trois Rivieres and Shawinigan at a plant called Les Forges.

Reports from all the French experts who examined the property showed the

ore to be suitable for reduction to pig iron, but it was not until the

examinations of Dr. Sarrazin in 1730 that Poulin de Francheville, a

Montreal merchant, organized a company. The operation was accelerated

in 1736 under the guidance of a French engineer named Vezain. The ore

was reduced by hardwood charcoal from timber obtained locally, and the

plant operated for 147 years until it was abandoned in

1883.

Coke smelting in Britain had come into use for the operation of

large-scale blast furnaces, but it was not until 1784 that it was

possible to turn iron pig into wrought iron by puddling. After this

time, the British iron output began to soar. Cranage and then Cort

improved the puddling operation so that separating and stirring gave air

access to the iron, decarbonizing it to the point that it became

malleable. The coal made no contact with the metal, and it was due to

the efforts of Cort that grooved rollers were first used in rolling.

Difficulties with acid slags and high phosphorus were not overcome until

metal furnace bottoms were made in 1816 in Monmouthshire.

While advances were being made in England and in Europe generally,

the American colonies had been developing their iron industry. In 1700

the colonies had produced only one-seventieth of the world's iron, but

by 1775 they produced one-seventh, with pig and bar production exceeding

that of England and Wales. Bar iron was not made, however, in the United

States until 1817 when a plant was started in Plumstock, Pa., and soon

after a similar operation was commenced in Pittsburgh, Pa. Already in

1790 a machine had been developed by Perkins in Massachusetts which

could cut strips and head nails in one operation to make the first

machine-cut nails.

Early Nailmaking. By the 18th Century wrought nails were fashioned

from metal plates rolled to the required thickness and slit by slitting

rollers into nail rods and "split rods" of various sizes depending on

the type of nail to be made. The rods were drawn to a point on the anvil

by hammering, then clamped at the untapered end by a vice and struck to

form a head. This was generally done hot. Even after the nailmaking

machine was invented in 1790, heads were generally formed by

hand-hammering until about 1825. From 1790 until 1810 machine cut nails

were made by setting the knife on a permanent diagonal, then the plate

was reversed, cutting nails with alternate heads and points. Larger

heads still had to be hammered. After 1810, a machine was developed by

which the blade was switched through an angle, cutting nails without

turning the plate.

Canadian Nail Manufacture. About the time that the first

nailmaking machine was invented in United States, John Bigelow opened a

small workshop in the St. Laurent suburb of Montreal to become Canada's

first nail manufacturer and founder of a company which later became part

of The Steel Company of Canada, Limited. The nail was particularly

precious at this time and was a much-prized commodity. Some men in the

American colonies were known to burn down old houses, with and without

the owner's permission, to collect nails from the charred ruins. Captain

Cook's sailors pulled them from their ships to trade them to the South

Sea Islanders. On the anvil each nail had to be hammered and shaped by

hand from bits of iron so that the nails were often so hard to come by

that builders still often laboriously fitted wooden pegs. The invention

in Massachusetts of a machine for cutting square nails from flat red-hot

strips of iron was an important advance in the industry and was soon to

be used in England as well as in Massachusetts to expand production.

John Bigelow survived the competition

of his counterparts by using one of the primitive American machines

himself. It was run by horsepower and cut the nails from the iron

automatically, but the nails still had to be headed by hand and he still

brought in his raw material in iron hoops from the wholesalers.

It is pointed out that the officers of the two opposing armies in the

War of 1812 probably had their horses shod with the help of Bigelow's

nails. Kilbourn points out that "war was not allowed to interfere,

except for the briefest periods, with anything so important as the flow

of the Richelieu valley trade and the regular functioning of customs

officers on either side of the river border."

Nail Analysis

Dr. Dove's analysis of the nails from Rocky Mountain House appears in

Table 11. He considers wrought iron nails to date to 1800 and before, cut

nails to date after 1810, and stamped nails to date between 1825 and

1830. These dates are pertinent to eastern Canada and the United States,

but the occurrence of wrought iron nails at Rocky Mountain House,

1799-1834, obviously indicates a continued use of this nail type well

into the 19th century in the Canadian West. Nelson (1963: 2) also points

out that wrought nails continued to be used for several decades

following the introduction of cut nails, and that they remained

superior for certain purposes, especially where clinching was

required.

From Dr. Dove's analysis in Table 11, various observations and

correlations can be made. At Rocky Mountain House wrought iron nails are

only slightly more numerous than cut iron nails. Of a total of 89 nails

identified according to mode

of manufacture, nine different techniques are represented.

Thirty-eight nails are hand wrought; 3 are wrought common; 3 are both

wrought and cut; 1 is wrought and machine finished; 1 is wrought and

early stamped; 31 are cut; 8 are cut common; 2 are entirely produced by

early machine, and 2 are entirely stamped specimens. This data indicates

that not all of the nails at the fort can be attributed to on-site

manufacture. Forty-eight specimens are products manufactured by machine

elsewhere and subsequently brought to the fort.

The types of nail heads represented can be synthesized and clearly

rosehead nails predominate at the site. Of 86 analyzable specimens

having heads, roseheads account for 52. Next in numerical frequency are

17 flatheaded nails; 7 csk. heads; 3 headless nails; 2 each of L-heads

and part heads; and 1 each of large rectangular, large rounded and

pinched head nails. A csk. nail is a special type with a circular shank;

they are not for general use.

When nailhead forms are tallied together with their mode of

manufacture, the following correlations occur: 24 roseheads are

wrought; 23 are cut; 3 are cut and wrought; 1 is wrought and machine,

and 1 is wrought and early stamp. The near equal occurrence of wrought

and cut roseheads is noteworthy.

Other correlations show that all of the wrought common, wrought and

cut, wrought and machine, and wrought and early stamped nails in the

collection are roseheads. In addition, 5 of the 8 cut common nails are

roseheads. Table 12 gives the complete list of nailhead-mode of

manufacture correlations.

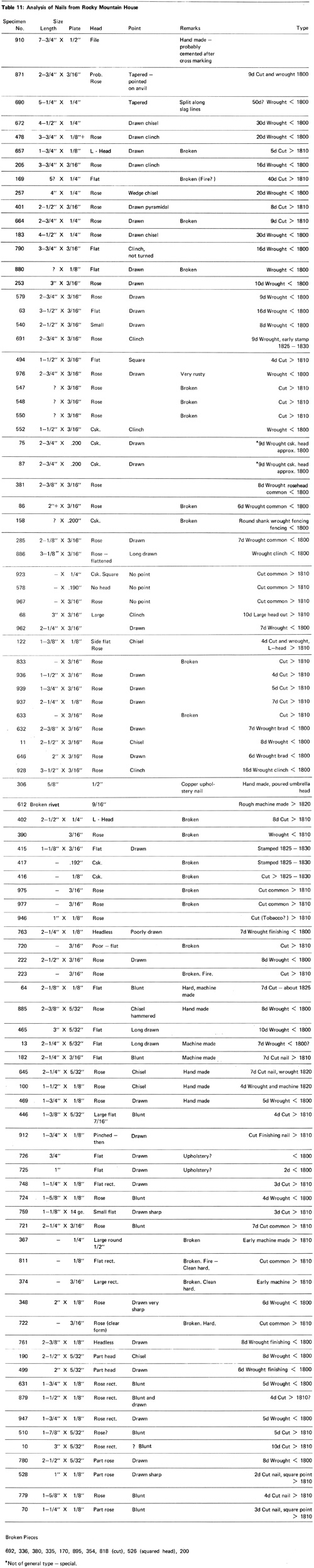

Table 11: Analysis of Nails from Rocky Mountain House

(click on table for a PDF version)

Table 12: Nail Heads and Mode of Manufacture |

| Head Type | Mode of Manufacture | Number | Size |

|

| Roseheads (52) | Wrought | 21 | 4-30d |

| Wrought common | 3 | 6-8d |

| Wrought and cut | 3 | 7-9d |

| Wrought and machine | 1 | 4d |

| Wrought and early stamp | 1 | 9d |

| Cut | 18 | 2-10d |

| Cut common | 5 | 7d |

|

| Flatheads (17) | Wrought | 5 | 10-16d |

| Cut | 6 | 3-40d |

| Cut and machine | 2 | 7d |

| Cut common | 1 | ? |

| Stamped | 1 | ? |

| Unknown | 2 |

|

|

| Csk. heads (7) | Wrought | 4 | 9d |

| Cut | 1 | ? |

| Cut common | 1 | ? |

| Stamped | 1 | ? |

|

| Headless (3) | Wrought | 2 | 7-8d |

| Cut common | 1 | ? |

|

| Part heads (2) | Wrought | 2 | 6-8d |

|

| L-heads (2) | Cut | 2 | 5-8d |

|

| Pinched (1) | Cut | 1 | ? |

|

| Large round (1) | Early machine | 1 | ? |

|

| Large rectangular (1) | Early machine | 1 | ? |

|

| Total |

| 86 |

|

|

Metallurgical Analysis

The metallurgical examination of the Rocky Mountain House nails

indicates that the nails are extremely soft and produced from puddled

iron. Dr. Dove selected five representative nails, 13, 41, 374, 465 and

818, for metallurgical examination. Number 13 is a flathead machine-made

7d wrought iron nail; 41 is a hand wrought rosehead with chisel point;

374 is an early machine-made large rectangular headed nail; 465 is a

flathead, 10d wrought iron nail; and 818 represents a portion of a cut

nail made for heavy driving. Longitudinal microsections were cut from

the heads of 374 and 818, photographed and then etched with 2 per cent

nital acid.

Samples 374 and 818 had numerous heavy complex inclusions with a

background rating of D+ (i.e., very heavy). The structure of sample No.

374 showed broad bands of

(a) Coarse grained ferrite (grain size 3-2-4 with a few 1's).

(b) Fine grained ferrite (grain size 7-6-8) with large carbides and

coarse lamellar pearlite.

The structure of sample No. 818 showed very little carbide with bands

of coarse grained ferrite that resisted nital etching, and bands of

finer ferrite. The general grain size was 5-6-4-3.

Dr. Dove remarks on the metal in the selected nails that:

There is no doubt that this material is puddled iron from the

nature of the inclusions. It is probable also that Sample No. 374 was

made from material which had been previously annealed to make it soft

enough to produce the large head shown on the sample.

Hardness tests and tensile strengths were also determined for the

metallurgical nail sample:

The approximate tensile strengths of these materials referred to

the Rockwell B hardness readings are shown beside the values so that you

will see that these nails were extremely soft in comparison to normal

nails of these dimensions which would have tensile strengths in the

order of 100,000 to 140,000 psr. This is characteristic of early nails,

particularly those produced from puddled iron.

Table 13: Rockwell B Hardness Tests on Sample Nail Shanks |

| Nail No. | RB | Tensile (Approx.) |

|

| 13 | 63-66 | 55,000 psi. |

|

| 41 | 66-70 | 60,000 psi. |

|

| 374 | 53-55 | 48,000 psi. |

|

| 465 | 63-67 | 55,000 psi. |

|

| 818 | 72-75 | 64-66,000 psi. |

|

Nail Sizes

Nail sizes are expressed in an anachronistic manner in terms of

price (d =pence) per hundred. The nail sizes from Rocky Mountain House

have an observable correlation with different types of nails. For

instance, the wrought rosehead nails have by far the greatest range in

size with 3d, 4d, 6d, 7d, 8d, 9d, 10d, 16d, 20d, and

30d sizes represented. Cut rosehead nails, on the other hand, are

restricted to smaller sizes: 2d, 3d, 4d, 5d, 7d, 8d, 9d, and 10d. The

cut flatheaded nails are similarly of small size except for one large

specimen: 3d, 4d, 7d, and 40d. Wrought flatheaded nails are larger at

7d, 10d, and 16d. This general pattern of cut nails being restricted to

smaller sizes may well be a reflection of the infancy of the cut nail

production.

Other Nails

In the analysis tables three nails, 169, 223 and 811, have been noted

"fire." Dr. Dove remarks that:

There is evidence that these samples were exposed to fire. This is

evident from the small amounts of coating of red iron oxide which have

appeared and which are

essentially a high temperature product. This might be of some

guidance to you in learning what went on in various areas.

The fired nails do offer interesting data. Specimen 169 is a

flatheaded cut nail dating 1810-25 from the interior western end of

building II. Specimen 223, a rosehead nail cut between 1810-25 comes

from pit 2 immediately northwest of building II. The third specimen,

811, is a flat rectangular head nail, cut common, and dating 1810-25; it

comes from pit 6 within building III. The distribution of these three

specimens covers a large triangle between pit 2 and buildings II

and III. There is consistency in their dates (1810-25) and proveniences

suggest burning during the Hudson's Bay Company occupation.

The two wrought csk. head nails have been marked "special" by Dr.

Dove. These nails exhibit a peculiar composite round and square shank

(Fig. 49, o), as compared to the purely round-shanked wrought

csk. "fencing" specimen (Fig. 49, n). Both "special" type

specimens date early (1800) and come from the interior of building I.

This building is believed to date to the North West Company

occupation.

49 Nails and sharpening file, a, flat head wrought clinch nail,

16d (pre-1800); b, wrought rosehead nail, 10d (pre-1800);

c, wrought flat head nail, Wd (pre-1800); d, wrought

rosehead nail, 16d (pre-1800); e, cut rosehead nail with drawn

point, 9d (post-1810); f, wrought rosehead nail, chisel point,

20d (pre-1800); g, wrought rosehead nail, drawn point, 30d

(pre-1800); h, large flat head cut nail, 4d (post-1810);

i, broken nail; j, L-head cut nail (post-1810); k,

wrought rosehead clinch nail (pre-1800); l, rosehead cut and

wrought nail, 9d (1800); m, wrought tapered head nail, 50d?

(pre-1800); n-o, wrought csk. head nails, 9d, special types from

building I (ca. 1800): p, handmade sharpening file of

pseudo-steel.

|

Nail Distributions

A further over-all view of the nail distributions within the fort is

informative. Of the total 100 recovered nails, the two most numerous

concentrations occur in buildings II and III; 28 nails are from building

II and 15 from building III. It is proposed here to list the various

features within the fort, together with the types of nails found in them

and their dates. No attempt is made to date a building on the basis of a

single nail.

Building I. Five nails recovered from this floored building

all date early 1800 or pre-1800. Nails 75, 86, 87, 917 and 962 are from

the building's interior. One of the nails, 917, has not been identified,

but the remaining specimens are all wrought nails. As mentioned

previously, the two 9d csk. "special" wrought nails are from this

building.

Building II. Nineteen loose nails are from this floored

building. Ten dating after 1810 (64, 68, 70, 100, 122, 169, 182, 833,

936 and 937), have a random distribution over the entire building. These

include four cut rosehead, three cut flathead, one wrought and cut

rosehead, one wrought and machine rosehead, and one large head cut nail.

The six nails of pre-1800 date (158, 183, 205, 499, 540 and 790), are

all from the vicinity of the double-hearth fireplace westward. Two of

these nails are wrought rose, one is wrought flat, one is wrought part

head, one is wrought small, and one is the wrought csk. head nail having

a completely round shank. Three other specimens remain unidentified. The

distribution of the early nails restricted to the western end of

building II as opposed to the wider over-all distribution of the later

nails is of note. This is highly suggestive of the presence of an

earlier structure in what later became the western end of the Hudson's

Bay Company building.

Building II (Pit 4). The two nails from pit 4, 285 and 286,

are both wrought common roseheads of 7d size. They date early, prior to

1800.

Building II (Pit 5). Three nails, 335, 336 and 367, came from

this pit. The one identifiable specimen, 367, is a large roundhead nail produced by

early machine methods. It thus dates 1810-25.

Building II (pit 15). The four nails from this pit, 547,

548, 550 and 552, all appear to date after 1810 but prior to 1825,

except for specimen 552. It is wrought csk. head clinch nail of

pre-1800 date. The three other nails are all cut roseheads.

Building III (Pit 6). All nails from the interior of this

unfloored building were from pit 6. Nail 354 is the only unidentifined

specimen of the 15 nails, 348, 354, 374, 528, 720, 721, 722, 724, 725,

726, 748, 759, 761, 763, and 811. All nails but five, 348, 724, 726, 761,

and 763, date between 1810 and 1825. The five nails of pre-1800 date

include two wrought rose nails (one from the 30-in. depth of the pit),

one flat upholstery nail and two wrought headless finishing nails. The

post-1810 nails include two cut common rose, one cut rose, two cut flat,

one cut common flat, one cut flat rectangular, and a large rectangular

early machine made nail. This latter specimen is from the 26-in. depth

of the pit.

Building IV. This floored building which extended across space

within both the original and the extended fort produced only six

analyzable nails, 446, 631, 632, 633, 645 and 646. Three are early

varieties and three nails post-date 1810. Of the three nails of pre-1800

date, two are wrought rosehead brads and the other nail is a wrought

rose. These three early specimens are all from proveniences within the

area of the old fort's boundary which was later covered by building IV

with the expansion of the fort. The three later nail types include a

cut rose, a cut flat and a wrought and cut rose.

These data suggest three possible explanations. The first is the

probable salvaging of nails from the original fort for use in

constructing building IV; second, the early nails are not a part of

building IV but are from the earlier fort, and third, both the early and

later types of nails date contemporaneously in this context.

Building VI. This ill-defined floorless building produced

five loose nails. These are specimens 672, 779, 780, 879 and 880. Three

of the nail types date early and two are of later post-1810 vintage. The

early specimens include a wrought rosehaed nail, a wrought flathead nail

and a wrought headless form. The later nail types are both cut rose

varieties. It seems probable that these nails are from the upper

surface of pit 10 rather than from the building itself.

Building VII (Pit 11). Six nails from pit 11 have a general

date between 1810 and 1825. Specimens from this pit are 578, 657, 885, 886, 923 and 967.

The top 6-in. level is represented by a cut common rosehead nail and a

cut L-head nail. Within an ash-filled layer 12 in. below the top of the

pit two wrought rosehead nails and a single cut common csk. square nail

were found in association with one another. This occurrence clearly

demonstrates contemporaneity of earlier type nails with later types on

the site. An additional cut common headless nail from between the upper

and ash-filled layers of this pit is also of post-1810 manufacture.

Pit 1. Only one nail, 306, came from this pit. It is a handmade

copper upholstery nail with poured umbrella head. A date for this type of nail is

uncertain.

Pit 2. This pit produced two nails, 222 and 223. Both are

roseheads, but while one is wrought the other is cut.

Pit 8. The three nails from this pit represent the latest

dating specimens from the site. Nails 415, 416 and 417 are from this

pit. Specimen 415 is a flat stamped nail of 1825-30; 416 is a cut csk.

head nail also of 1825-30 date; and 417 is a stamped csk. head of

1825-30. This late date for the nails agrees favourably with the

temporal position of other specimens from this pit.

Pit 10. Five nails from pit 10 have a nearly identical

temporal span noted for the loose nails from building VI. Two specimens,

947 and 976, are wrought roseheads of pre-1800 date. Two others, 975 and

977, are cut common roseheads dating after 1810. The third specimen is a

cut (tobacco? ) rosehead nail which dates post-1810. In general, this

pit is of probable 1800 to 1825 date according to Dr. Dove's sequence of

nail dates.

Pit 12. Pit 12 produced a single nail, 928, a 16d early

wrought rosehead clinch nail of pre-1800 vintage.

Surface Ash Dump East of Fur Press. The one nail, 579, from

this ash dump is a wrought rose type.

Surface Ash Dump Near Building IV. Two nails, specimens 401

and 402, from this ash dump post-date 1810. One is a cut rose nail; the

other is a cut L-head.

Surface West of Building II. Four nails from the area west of

building II and between pit 2 and building II are early types. Two, 253

and 257, are wrought rose; another, 381, is a wrought common

rose. From the western exterior palisade trench northwest of building

II, a wrought rose nail, 390, was also recovered.

North Exterior Palisade and North Corner Bastion Area. Four

nails from these areas of the fort are all early types. Nails 465, 478

and 871, all early wrought nails of large size, 9d to 20d, are from the

exterior palisade trenches flanking the north corner bastion. A single

hand-wrought 5d rose nail, 469, came from within the north corner

bastion. It is interesting to note that all nails found within the

exterior trenches of the old fort are early varieties and, indeed, such

nails only occurred in the palisade trenches bounding the northwest,

north and northeast sides of the fort.

Stain Feature. One cut nail, 818, came from the boat-shaped

stain feature in the northeast corner of the fort. This nail is a

post-1810 type used for heavy driving.

Nails from South of the Fort. Four nails, 510, 526, 690 and

691, are from excavated areas outside the south end of the extended

fort. One is a broken square headed nail; another is a wrought headless

nail of large 50d size; another is a cut rose; and the final specimen

represents a wrought and early stamped rose clinch nail of 1825-30.

Observations

From this analysis come several observations. First, hand-wrought

iron and cut iron nails are nearly equally represented at the site. Both

types appear with roseheads which are the dominant nailhead form.

Second, there are some nails completely manufactured or finished by

early nail machines. Such machines were usually water-, horse-, or

hand-powered. The possibility that such a machine existed at the fort is

remote, and thus the inference that all nails were made on the site is

precluded.

Third, although Dr. Dove's dating of the various nail types is

consistent with the development of nails in eastern Canada, Europe and

the United States, it is not altogether suitable for dating the

structures at Rocky Mountain House. It appears that early wrought iron

nails have considerable contemporaneity and overlap with the later cut

and machine made nails.

Fourth, most of the cut nails are of small size. This may well

indicate the state of infancy of the cut nail manufacturing technique

at the time Rocky Mountain House was occupied.

Fifth, there is a clear correlation of wrought iron nails in

association with the exterior palisades bounding the northwest, north

and northeast sides of the fort. These palisades date to the earliest

construction of the fort. In addition, there is a distinct restriction of

wrought iron nails in the western end of building II. This suggests the

possibility that an earlier building than the Hudson's Bay Company

structure was in that locale.

Sixth, although there is no one nail type which can definitely be

designated to date to the North West Company occupation, some of the

wrought iron nails and the special csk. head nails are probable

candidates.

Copper Rivet

This broken specimen, 612, is the only rivet from the site (Fig.

47, a). The head is 9/16 in. in diameter. According to Dr. Dove this

item is rough machine made and would post-date 1820. Its provenience

within building V supports this date.

Copper Tack

This specimen, 306, is a copper upholstery nail. (Fig. 47,

b). it is handmade with a 0.5 in. poured umbrella head. Length of

the tack is 5/8 in. It is from pit 1. Dr. Dove (1967:3) notes that:

Copper nails were used during that period in order to obtain large

heads and in order to avoid severe corrosion in smoky atmospheres or due

to extremely acid woods. These cases do not appear to fit the

circumstances.

Could it not be that a tack like this came from a luggage trunk, such

as the one which appears to have been sunk in pit 5?

Iron Hoops and Fragments

Seven complete iron hoops and 30 small hoop fragments are represented

in the excavated artifact sample from Rocky Mountain House. Six of these

hoops were found folded and nested together at the 28 in. depth of pit

14 within building V (Fig. 34). All measure 2.5 cm. wide by 3 mm. thick.

Two of the hoops have diameters of 26.9 cm.; two are 45 cm. wide, and

two measure 56.3 cm. in diameter. All are fastened together by large

iron rivets. The fact that these hoops are neatly folded and nested flat

inside one another precludes the possibility of their position being

attributable to normal crushing and disintegration of a barrel. Such action would

leave the hoops randomly dispersed at any number of angles. Much more

reasonable is the interpretation that these six iron hoops represent a

forgotten iron cache. It will be noted in Dr. Dove's historical outline

of early nailmaking (See pp. 124-27) that iron for the

manufacture of nails was commonly purchased in iron hoops from

wholesalers. This group of six iron hoops was probably intended for nail

making. The provenience in pit 14 lies well within the area of the

extended fort under building V which dates to Hudson's Bay Company

times.

The seventh iron hoop is also from a pit, but one in which other

debris was randomly scattered. This single-riveted hoop came from the

30-in. depth of pit 12 in the north corner of the fort. It measures 2.5

cm. wide by 2.5 mm. thick and has a hoop diameter of 24 cm. The hoop has

inwardly tapering sides for fixture over the end of a small nail, powder

or spirits keg. The random inclusion of other rubbish in this pit does

not suggest that the hoop was expressly buried as an iron cache.

Thirty other fragments of iron hoops were distributed over the site.

These are cut portions on either side of the rivet fixture. The

possibility that these are rejects from hoops used for nail manufacture

seems reasonable. If so, then trouble was not taken to remove the rivets

binding hoops together during the nail-making procedure.

Files

Three files came from localized areas within the fort. The first (Fig.

51, f) is a small portion of a three-sided iron file with the tang juncture

intact. Total length of the specimen is 2.6 cm., of which 8 mm. composes

the rectangular tang. The width of the file measures 1.4 cm. and its

height 1.2 cm. File teeth occur on all three sides and are

unidirectional and parallel. There are 16 teeth per cm. This specimen

came from between the floorboards of building I.

The second file (Fig. 51, h) is an incomplete steel specimen

with trapezoidal cross-section. The basal width of the file is 1 cm.

while the dorsal width is 5 mm. Thickness of the file is 1.1 cm. With

the tip of the file broken, the specimen's length measures 10.6 cm. of

which 4.3 cm. is the well-preserved rectangular tapering tang. File

teeth are only present on the flat ventral and two sloping sides. These

are quite fine, numbering 22 per cm., and are all unidirectional and

parallel. This file came from pit 5 within building II.

The third file (Fig. 49, p) has been identified by Dr. Dove

(1967: 4):

I do not believe item 910 to be a nail. I believe that this is a

sharpening tool which was held in the hand, and that it would be a

cemented product resembling steel which has been formed, surface marked,

and then hardened. Such a tool would be used for scythe sharpening or

small tools in the field.

It is also pointed out that this specimen was handmade. It measures

17.5 cm. long by 1.9 cm. wide by 1.3 cm. thick, and came from the 3 in.

depth of the west edge of pit 11, thereby dating quite late in the

fort's history.

50 Wedges, awls and punches. a, large iron axe wedge from pit

15 in building II; b, smaller iron axe wedge from building II; c-d,

eyeless wire fishhooks from pit 15 in building II; e, double-pointed

offset awl from pit 6 in building III; f, large offset awl from

building I; g, small iron punch from building II; h,

large iron punch from southwest of the fort; i, brass spigot from

building III; j, straight shanked table fork from near drainage outlet 2.

(click on image for a PDF version)

|

Iron Punches

Two complete hand-wrought iron punches are represented in the

ironware sample from the site. The first and smaller specimen (Fig. 50,

g) measures 7 cm. long, with a tapering tang 2.5 cm. long. The

main segment of the punch is square, measuring 4 mm. wide, and tapers to

a sharp point. This specimen came from north of the double-hearth

fireplace in building II.

The second iron punch (Fig. 50, h) is larger and of a

different style. Measuring 10 cm. long, this punch has no distinguishing

tang juncture. The punch is rectangular in cross-section,

measuring 4 mm. by 5 mm., and tapers to a point at one end. It is from

an excavated area southwest of the fort proper.

Offset Awls

Two double-pointed iron awls with a Z-shaped offset at the middle

were recovered. Two sizes are represented. The smaller square specimen

(Fig. 50, e) is nearly complete having only the tip of one end

broken off. It measures 5 cm. long with a maximum width and thickness

of 3.5 mm., and came from pit 6 within building III.

The second specimen (Fig. 50, f) is much heavier, but has part

of one pointed end broken off. The awl is square with a maximum width

and thickness of 6 mm. The length of the one complete prong measures 8

cm. from the awl tip to the centre of the offset section. This specimen

is from the eastern interior of building I.

Offset awls are found on many historic sites dating between 1740 and

1830. One is illustrated by Woodward (1948: 6) in

his depiction of select trade goads of 1748. Maxwell and Binford (1961:

88) recovered nine specimens dating to the early 1760s at Fort

Michilimackinac, and one specimen is recorded from Kipp's Post

(Woolworth and Wood 1960: 274). Either end of such double-pointed awls

could be used as a hafting tang with the offset acting as an efficient

brake against deep penetration of the tang into the awl handle.

51 Knife blades, files and fork, a, steel clasp-knife blade from pit

1 bearing the word REAGLE; b, steel crooked knife from pit 8; c,

steel clasp-knife blade from pit 11 bearing the word BATEMA or RATEMA:

d, iron clasp-knife blade from building I bearing the letter D;

e, lead sinker from building V; f, portion of three-sided

iron file from building I; g, hand-wrought iron cold chisel from

building II; h, steel trapezoidal file from pit 5 in building II;

i, portion of a slate pencil from pit 10; j, folding sheath fork

with brass foil side cover from drainage pattern adjoining pit 1.

(click on image for a PDF version)

|

Cold Chisel

This hand-wrought iron chisel (Fig. 51, g) measures 7.2 cm. long with

the shank being 4.9 cm. long by 8 mm. wide and 5 mm. thick. The top of

the shank has been folded over at right angles to form a hammering

platform 9 mm. long by 7 mm. wide. Hammer marks cover the top of the

platform. The distal cutting blade of the chisel has been formed by

flattening the shank; the straight-based cutting blade measures 2.3 cm.

long by 1.3 cm. in maximum width. This cold chisel was recovered near

the double-hearth fireplace in building II, and may have been used in

splitting the sandstone rocks for that structure.

Iron Wedges

Two flat tapering iron wedges are both from building II. The larger

specimen (Fig. 50, a) measures 5.5 cm. long by 4 mm. thick. Its width

tapers from 1.6 cm. to 6 mm. at the distal end. This specimen came from

pit 15 within building II.

The smaller wedge (Fig. 50, b) measures 4.5 cm. long by 5 mm. thick.

Its width tapers from 1.2 cm. to 6 mm. This specimen was found loose by

the western edge of the double-hearth fireplace in building II.

Wedges such as these are used to expand the head of an axe

handle.

Knives

Four knife blades from the fort are of interest in terms of their

style and the manufacturers' marks they bear. Unfortunately, attempts

to trace the authorship of these marks have proved futile. The British

Museum, the London Museum and the Sheffield City Museums have only

incomplete records of cutlers' marks for the 18th and 19th centuries.

Many of these records have been lost or destroyed in the past.

Three of the knife blades are from clasp-knives broken at the pivot

hinge. The fourth blade is from a crooked canoe or snowshoe knife.

The first clasp-knife blade (Fig. 51, a), made of steel, measures 7.4

cm. long by 1.7 cm. in maximum width. Its upper edge, measuring 2 mm.

thick, slopes sharply to the point. The base of the blade curves toward

the hinge juncture. The word REAGLE in capital letters is stamped on the

upper left hand side of the blade near the butt. This specimen was

recovered in the top 6 in. of pit 1 in the northwest corner of the

fort.

The second clasp-knife blade (Fig. 51, c) is also of steel. It

is a large blade measuring 8.3 cm. long by 1.9 cm. wide. The upper edge

thickness is 3 mm. and both dorsal and ventral blade surfaces slope

gradually to a point. The basal butt of the blade curves toward the

hinge juncture. Along the upper left side of the blade are stamped

distinctly the letters ATEMA. Less distinct and in front of the

A is the letter R or B. This specimen dates late in terms of its

context within the top 6 in. of pit 11.

The third clasp-knife blade (Fig. 51, d) is severely corroded

iron. It measures 7.6 cm. long by 2.0 cm. wide and 3 mm. thick. The

dorsal and ventral blade surfaces taper gently to a point, but in

contradistinction to the two previous specimens, the basal butt does not

curve. It is simply indented squarely. Only one letter, a D, is

discernible high up in the left hand corner of the blade. This specimen

is from building I.

The fourth knife blade (Fig. 51, b) is a steel crooked knife.

With the rectangular tang broken, the specimen has a length of 9.4 cm.

The curved blade measures 7.5 cm. long, and has a maximum width of 1.6

cm. at the butt. This width tapers to 1.0 cm. at the blade tip. The dorsal

thickness of the blade is 3 mm. The blade curves 33 degrees left of the

normal blade angle. While the left side of the blade is flat, the right

side is distinctly bevelled and warped to account for the curve. The

bevel begins 8 mm. from the top of the blade and runs the entire length

of the tip; it represents the starting line of an inslope to form the

sharp blade edge. Stamped indistinctly on the upper left hand butt end

of the blade is a square symbol displaying four petals radiating from

the centre of the square to its four corners.

This crooked knife blade has a late dating provenience at the fort in

pit 8 outside the south gateway. Such blades were usually supplied by

the Hudson's Bay Company without any handle (Woodward 1948: 6), thus

allowing the individual to fashion his own. The knife is

used much like a drawknife in making snowshoes or trimming canoe

ribs.

Whetstones

Two whetstones of grey dolomitic rock are included in the inventory

of tools and hardware. Both are long, rectangular cobbles, probably from

the river nearby. The first specimen measures 13.2 cm. long by 4.7 cm.

wide and 2.0 cm. thick. It has been ground flat and striated on one face

only. It was found loose within the southwest corner of the fort.

The second specimen measures 9.1 cm. long by 2.8 cm. wide by 1.4 cm.

thick. It is abraded on two faces and was recovered from a low level of

pit 12 in the north corner of the fort.

Alexander Henry the Younger remarks on the use of stones from the

North Saskatchewan River near the fort for sharpening tools. He relates

(Henry 1897: II, 702):

Both sides are rocky, and the current is very strong where,

rushing among the large stones, it forms several cascades. The stone is

light gray, some of it inclining to whitish and yellowish. It is

excellent for sharpening axes and other tools; when found of a proper

shape it answers for grindstones, nearly as good as those from

Europe.

Latch

One small 3.5 cm. long latch came from the site. This is a

round-shanked iron specimen with a flat circular end perforated by a 4

mm. wide hole. A small nail could be used through this hole to make a

swinging hinge. The latch is of a size suitable for attachment to the

front of a box or chest. It comes from within the southwest bastion.

Pintle

A wrought iron pintle has a total length of 23.5 cm. of which 14.5

cm. represents a long square shank which tapers and curves to form a

round, hooked end. It was found in the turf between pit 11 and the

eastern wall of the exterior palisade.

Clear Window Glass

Two pieces of clear window glass came from the same area of the fort

(Fig. 45, j). These pieces are very thin, 1.5 mm. They were found along the

east wall of building I near the northeast corner, suggesting the

presence of a small window in that part of the building.

Miller (1960: 67) states that early 19th-century glass is very thin

at 1 mm. and is colourless. This description conforms to the few

fragments from Rocky Mountain House. Certainly window glass must have

been a rare and perhaps costly item to bring to the fort. Commonly

windows were simply covered with a skin parchment flap (Harmon 1957:

137; Moberly and Cameron 1929: 95).

Threaded Lead Tube

This threaded lead tube has not been identified according to any

specific function (Fig. 46, n). It measures 4.1 cm. long by 1.9

cm. in diameter, and the lead walls of the tube are 5 mm. thick. The

specimen appears to have been mould made with a smooth exterior. Inside

large coarse threads spiral down the length of the tube. The specimen

has been severed and broken at one end, probably with a chisel. It was

loose in the turf west of the northwest end of building II.

Silver Fragment

A small, unidentifiable cut silver strip, 1.3 cm. long, came from pit

10 within building VI.

Copper Strap

This heavy copper strap is bent at right angles at each end. Its

total length is 19.7 cm., with a width of 3.2 cm. and thickness of 3

mm. At each end there is a square hole 5 mm. wide. It was excavated

outside the fort, directly south of building IV and east of the south

corner bastion. It appears to be a piece suitable for partial

encirclement of a square beam or post.

Sheet Copper Fragments

Fourteen pieces of cut sheet copper were present at the site. These

were cut from copper pails or kettles. Distribution of the copper

fragments shows a close correlation with buildings within the fort, and

several came from outside the south end of the fort as well.

Table 14: Distribution of Sheet Copper Fragments |

| Provenience | Number |

|

| Building II (west end) | 4 |

|

| Building II (east end) | 1 |

|

| Building III (pit 6) | 1 |

|

| Pit 10 | 2 |

|

| Ash above pit 3 | 1 |

|

| Fill around post 36 | 1 |

|

| Outside fort to south | 4 |

|

| Total | 14 |

|

Tin Fragments

Twenty-three pieces of thin disintegrating tin came from random

distributions over the site. The presence of tin on the site is by no

means anachronistic. The manufacture of tin cannisters, plates, and

other articles, extends well back into the 18th century (Fontana and

Greenleaf 1962: 67).

|